YAMASHIN Nano Filter™ is a groundbreaking

new material that will improve society.

In 1978, YAMASHIN developed and produced a glass fiber

that is used for in-house filter element production.

This specially-developed technology has made Yamashin a global

top niche filter manufacturer in the construction machinery field.

In 2017, Yamashin developed and succeeded

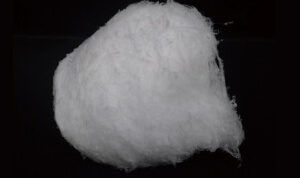

in the mass production of nanofibers (YAMASHIN Nano Filter™).

With YAMASHIN Nano Filter™,

Yamashin is embarking on a new challenge - to enter into

new fields beyond the filtration business.

Huge Possibilities

YAMASHIN Nano Filter™ presents the possibility of leading

a paradigm shift in the materials sector

that could not previously be solved using conventional materials.

of resin

materials

- Adjustable melting point : 200 ~ 320 °C

- The most suitable resin can be selected

diameter

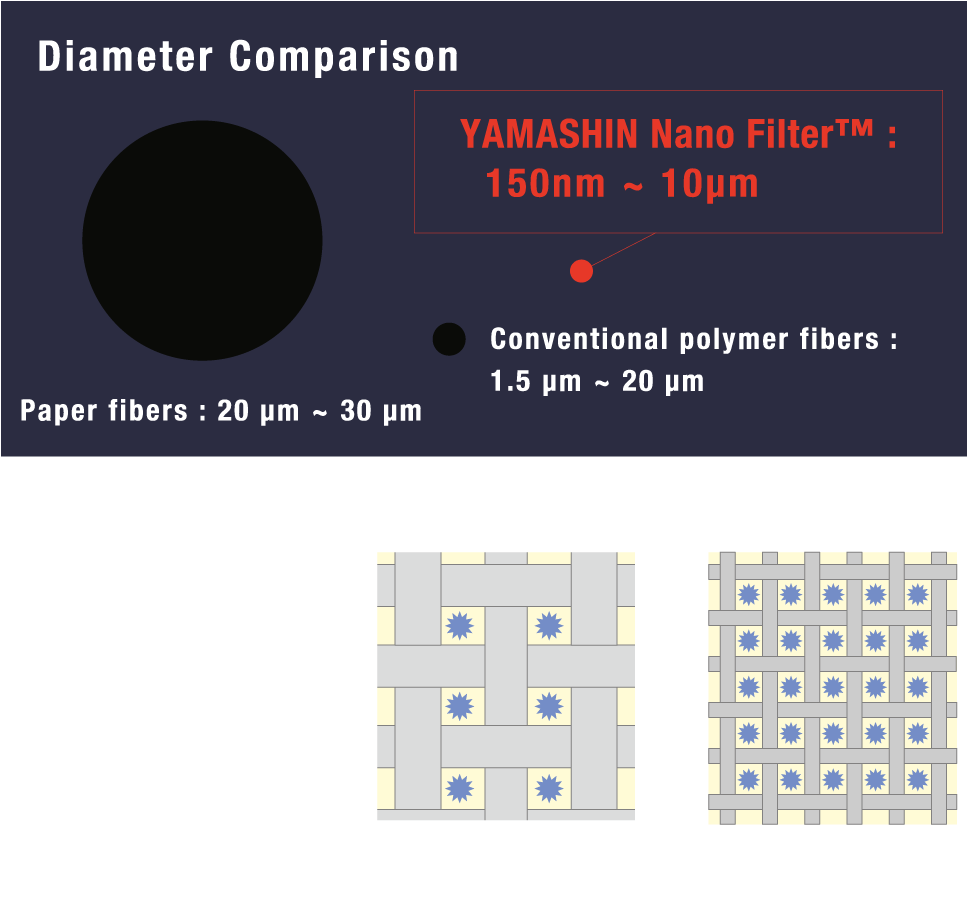

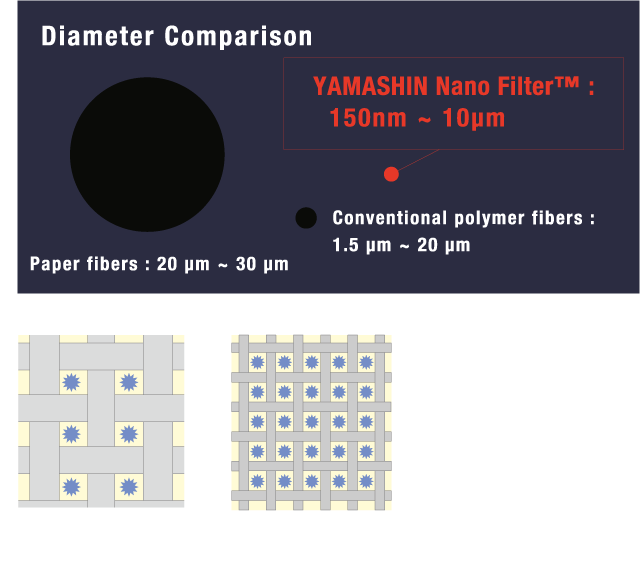

- Adjustable diameter : 150 nm ~ 10 μm

- The fiber diameter distribution can be selected specifically, as required

properties

- High porosity / high surface area

- High sound absorption, heat insulation,self-extinguishing properties (non-combustibility / flame retardance)

Adjustable to meet customers’ specific requirements

The YAMASHIN Nano Filter™ technology, which is adjustable for a wide range of melting points , allows a large choice and combination of resins.

Moreover, the fiber diameter can be adjusted to values between 150 nm and 10 µm. Resins, when thinned down to the nano level, will have new characteristics, such as high polarity, larger specific-surface area, self-extinguishing (flame retardant) , and heat/sound insulating properties that the materials don’t innately have. Using this technology, it is now possible to meet the customer needs that were not possible using conventional filter media.

Nanofibers are defined as a fibrous form of material having a diameter of 1 nm ~ 1,000nm (1μm).

New physical properties can be obtained by thinning fibers to the nano level. By using this mechanism, Yamashin is currently developing various new raw materials.

Features

YAMASHIN Nano Filter™ can be created using a wide range of

polymers with different properties

YAMASHIN Nano Filter™ can be used to solve problems in application areas that cannot be addressed using conventional methods.

If you have a polymer type that cannot be used for a particular application area, please contact us.

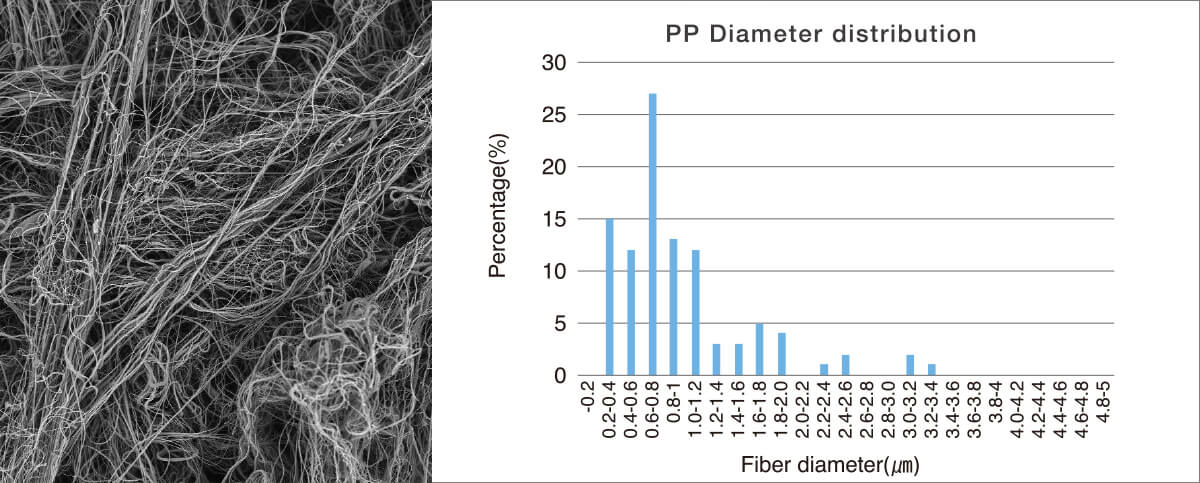

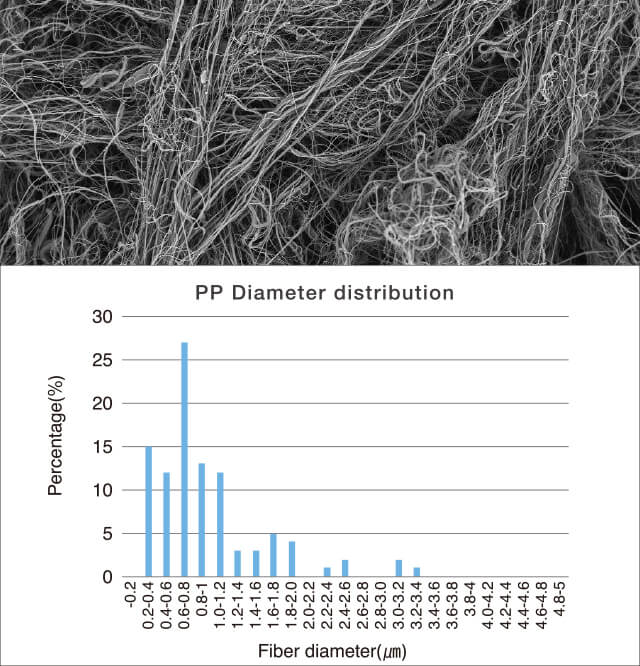

Fiber diameter distribution of

For example, when using PP (polypropylene) as the raw material, we can produce fiber diameters from 200nm ~ 3μm, with a peak diameter of 600 nm ~ 800 nm.

it is possible to produce diameters smaller than those obtained when using PET as the raw material.

Unique Production Method

The YAMASHIN Nano Filter™ production method

has various advantages over other methods

Comparison (Pros & Cons)

| Pros(+) and Cons(-) | |

|---|---|

| Yamashin’s Melt-blown method | + Various thermoplastic resins can be used + Adjustable diameter (150 nm ~ 10 μm) + Able to create different fiber structures (sheet form, cotton form, etc.) + Easy maintenance + Good productivity |

| Composite Spinning method | + Uniform thickness, varying cross-section + Minimum fiber diameter of 150 nm + Suitable for thin films and medical field use − Large equipment cost (min. 3 billion yen) − Solvent required |

| Electrospinning method (ESD method) |

+ Ultrafine fiber with diameter of several 10 nm (1g/m2) + Heat sensitive substances can be turned into fibers − High introduction cost − Low productivity and low manufacturing safety |

| Ordinary Melt-blown method | + Good productivity − Production of ultrafine fiber diameter impossible − Smallest diameter of roughly 800nm (fine tuning difficult for production of 1 μm or less) |

Applications

YAMASHIN Nano Filter™ can be utilized in a wide range of

industrial fields and applications

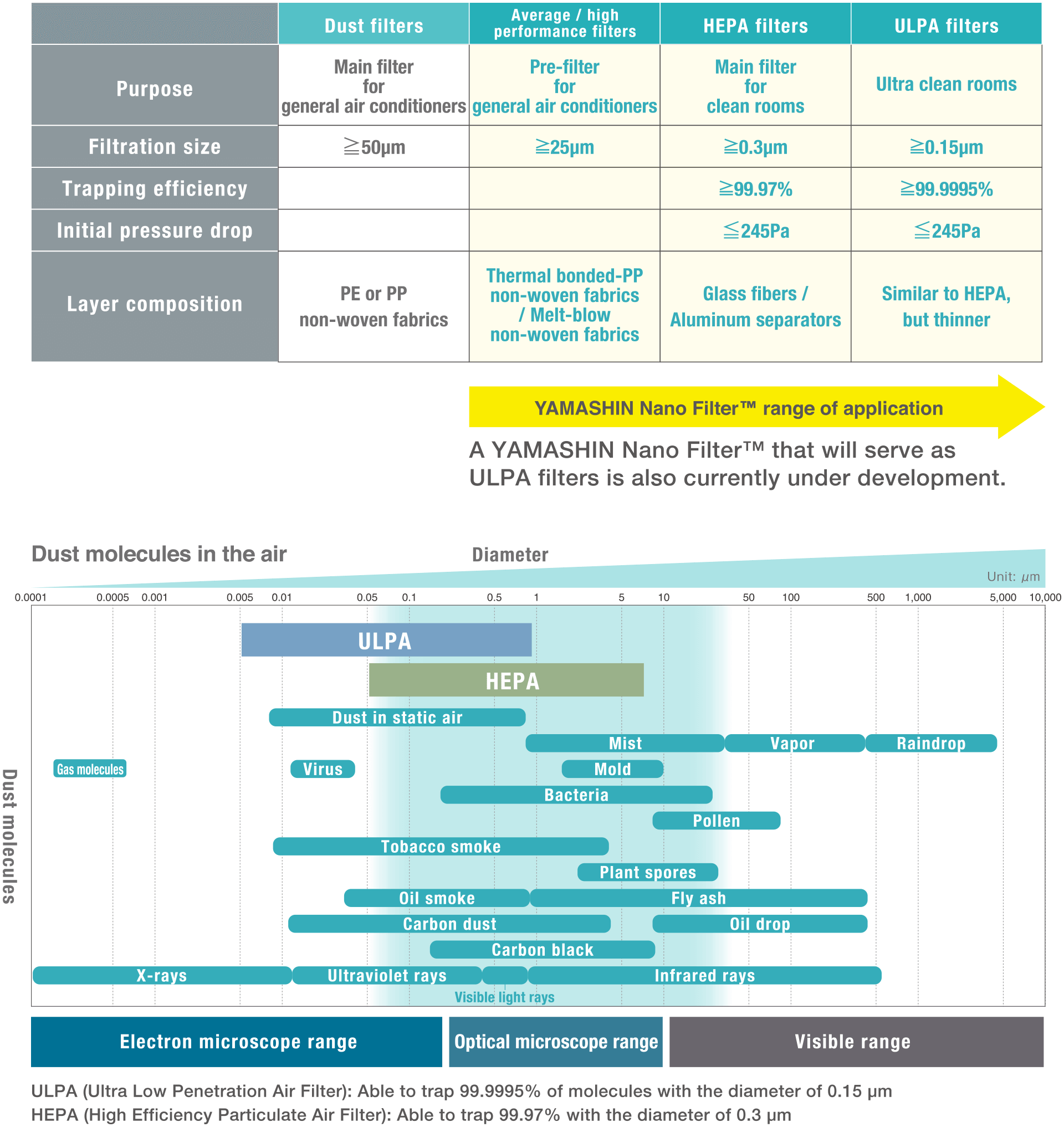

Air Filtration

- High trapping efficiency

- Small pressure drop

- High trapping amount

- Deodorization & Absorption

- Sterilization

features suitable for air filtration

More compact and lighter,

with higher performance

Due to its significantly smaller diameter (150 nm ~ 10 μm), YAMASHIN Nano Filter™ displays a higher trapping efficiency, smaller pressure drop, and higher performance compared to conventional products, and is also more compact and lighter. Addition of extra features (deodorization and sterilization, etc.) is also under development by harnessing its large surface area.

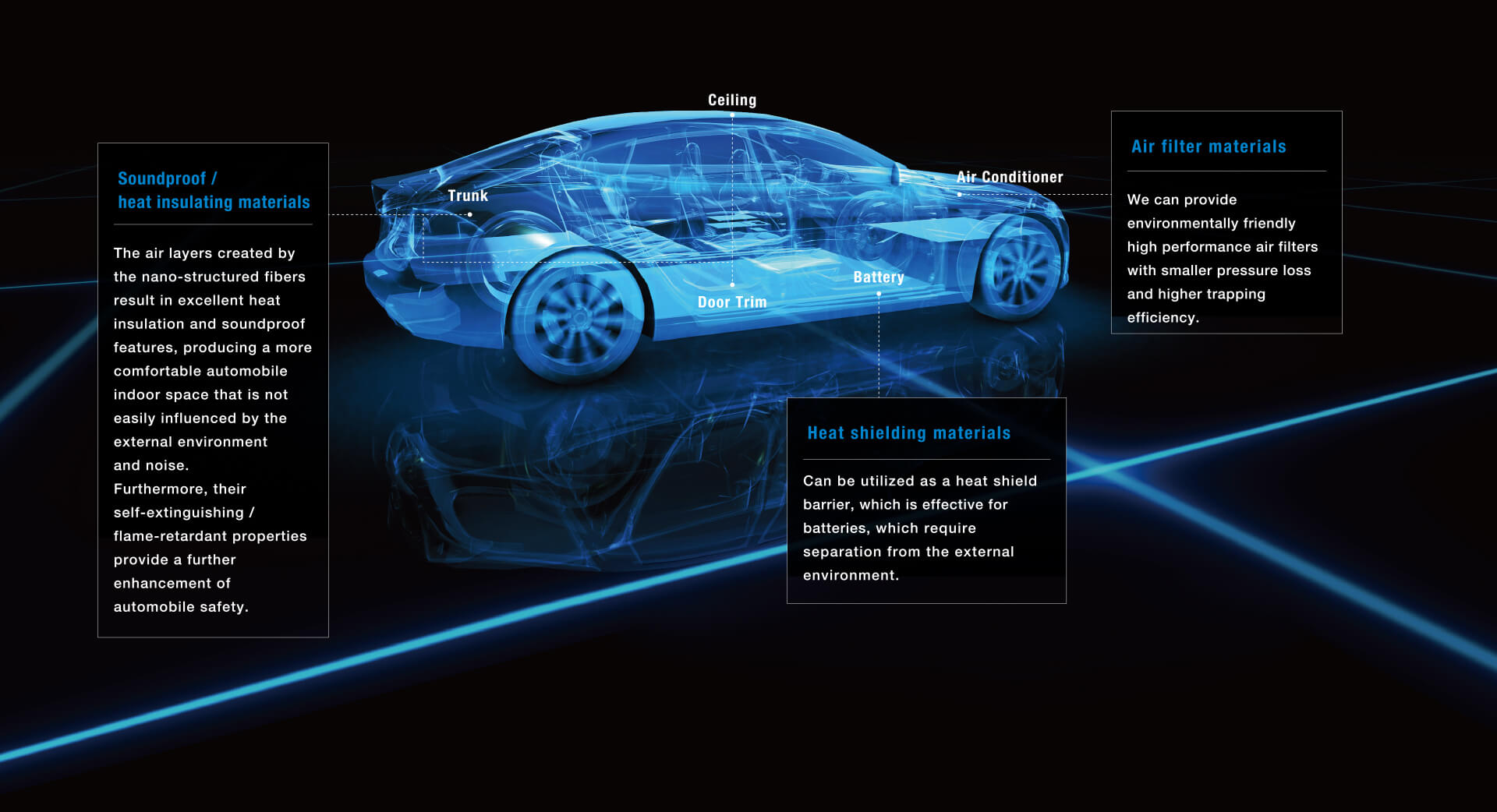

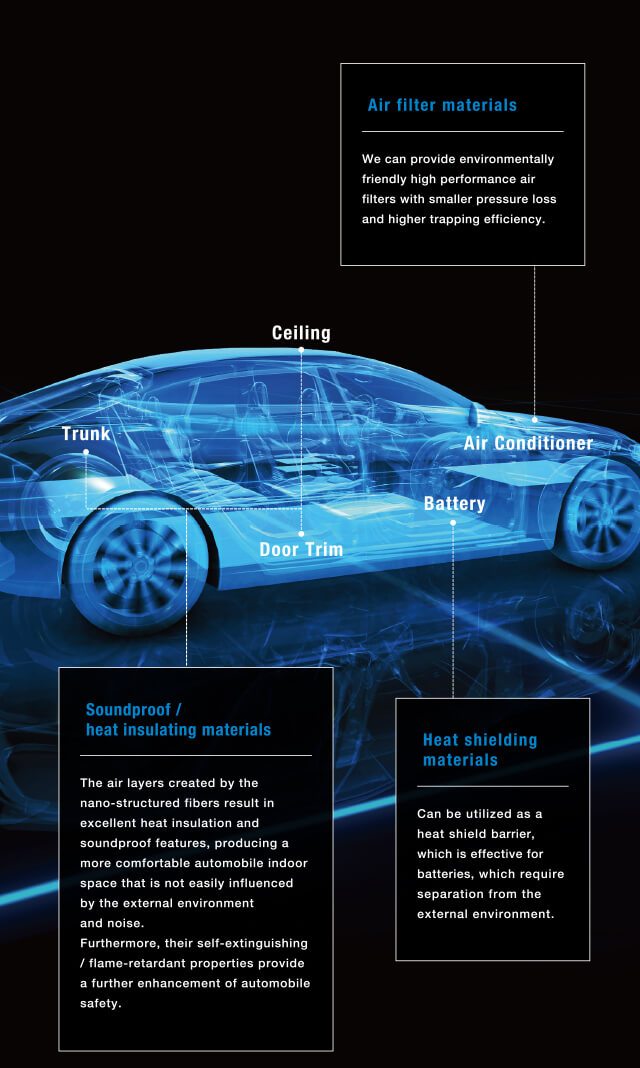

Automotive

Applications

- High porosity

- Self-extinguishing / Flame-retardant

- Sound proof

- Light weight

- High heat insulation

features suitable for automotive applications

Making future automobile

environments more comfortable

By harnessing its excellent self-extinguishing / flame-retardant and soundproof and heat insulating properties, YAMASHIN Nano Filter™ can be employed as a highly heat insulating, soundproof material, realizing a safer and more comfortable automobile indoor space.

Furthermore, we can also provide lighter-weight, environmentally friendly air filters and battery heat shielding materials with higher performance.

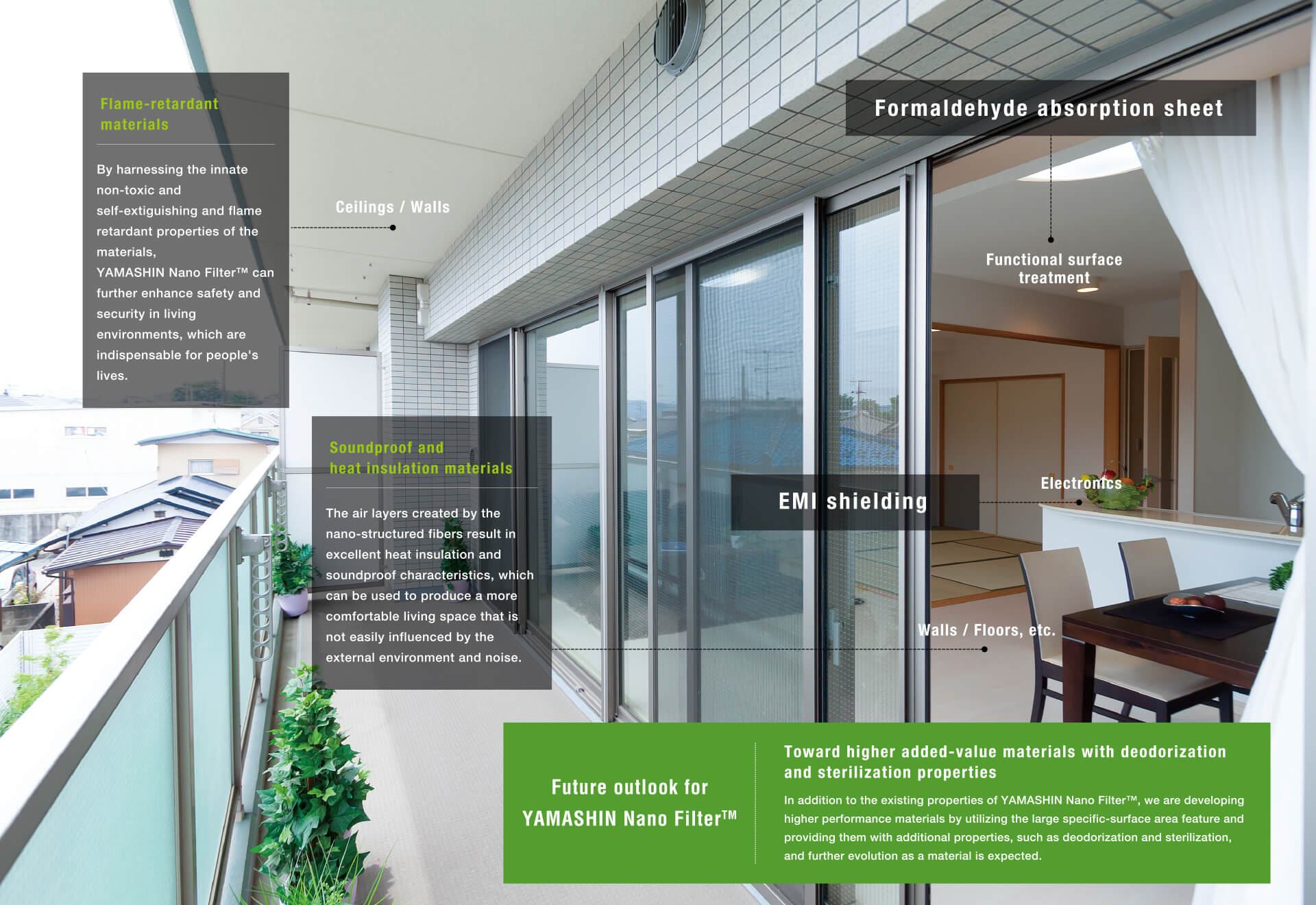

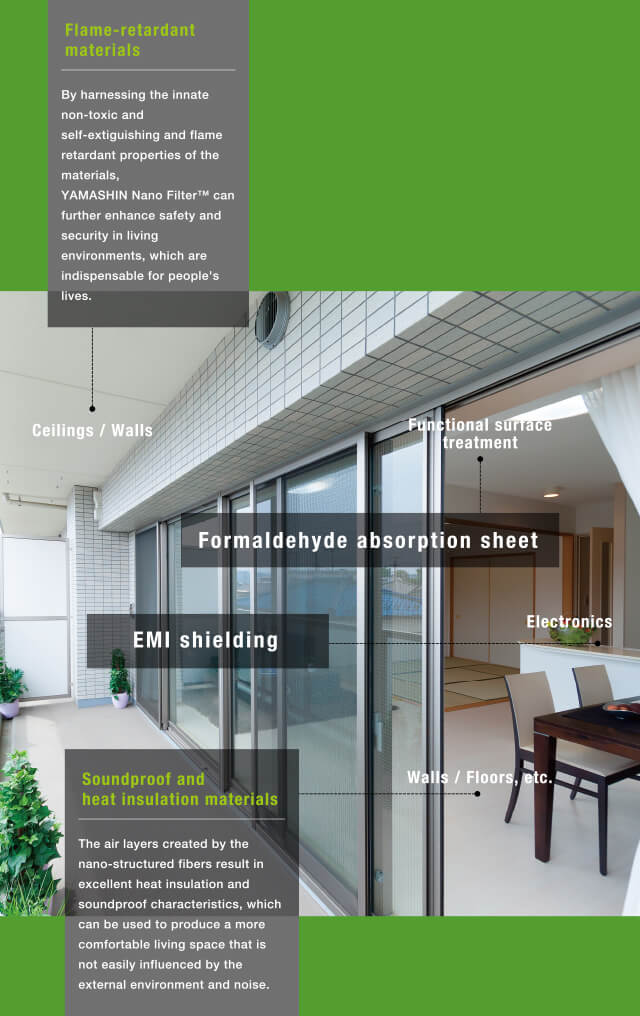

Construction

Materials

- High porosity

- Self-extinguishing / Flame-retardant

- Sound proof

- Light weight

- High heat insulation

features suitable for construction materials

Supporting comfortable,

ecological living

YAMASHIN Nano Filter™ has great potential for building materials.

For example, it can be used as a flame-retardant material for ceilings and walls due to its self-extinguishing properties, a soundproof material for walls and floors, and a toxic substance absorption sheet, etc. YAMASHIN Nano Filter™ not only improves living comfort in a cost-effective manner, but is also people and environmentally friendly.

Future outlook for

Toward higher added-value materials with deodorization and sterilization properties

In addition to the existing properties of YAMASHIN Nano Filter™, we are developing higher performance materials by utilizing the large specific-surface area feature and providing them with additional properties, such as deodorization and sterilization, and further evolution as a material is expected.

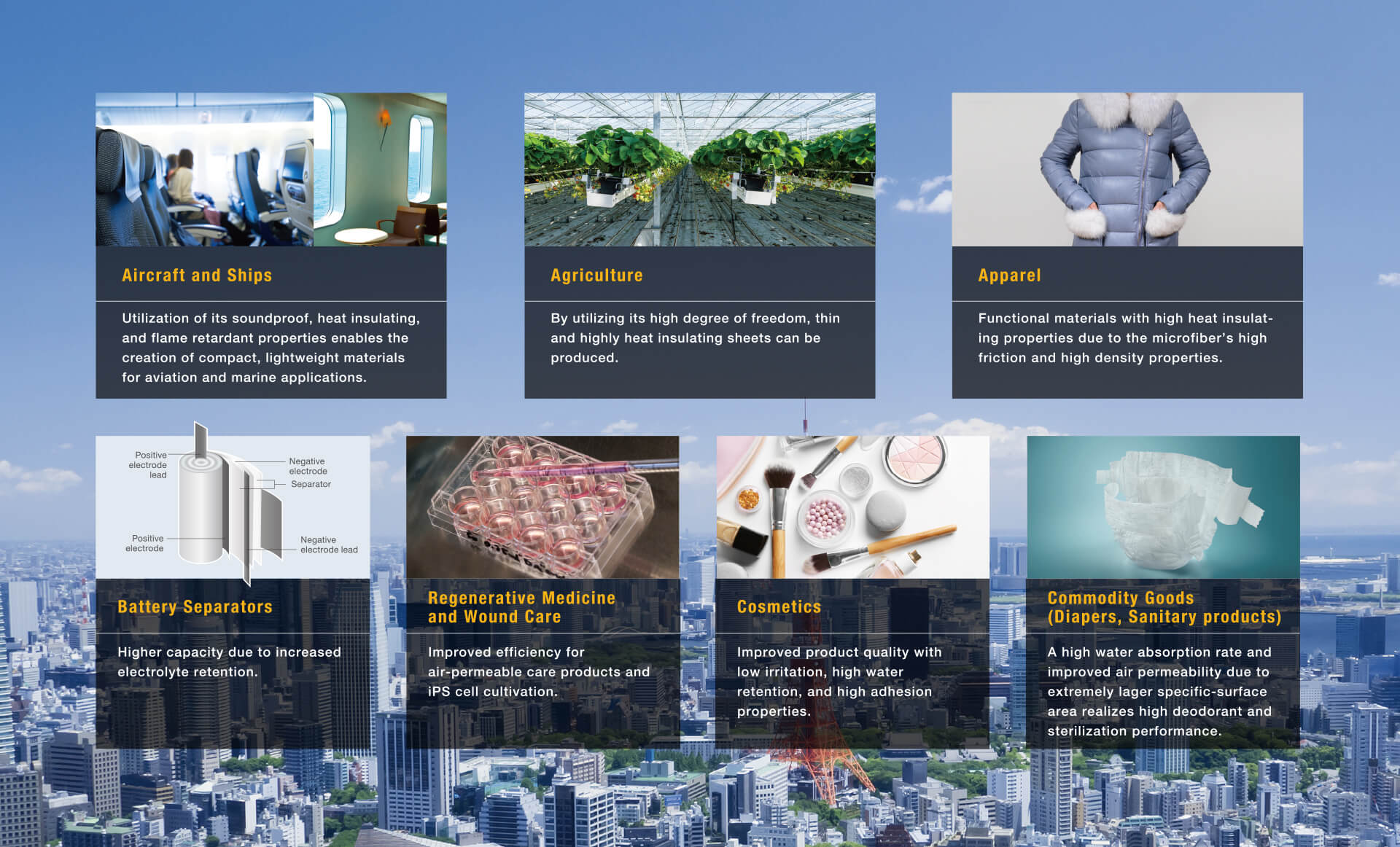

Society

Possibilities for Social and Industrial

Applications

With the expectation of cost and application advantages over conventional products in a wide range of fields, including electronics, medical / biotechnology, agriculture, apparel, cosmetics, and daily necessities, in the future, YAMASHIN Nano Filter™ will contribute to realization of a prosperous society, by serving as an indispensable material for people’s lives.

Contact us: YAMASHIN-FILTER CORP.

1-1-8 Sakuragi-cho, Naka-ku, Yokohama 231-0062, Japan

FAX:(Sales section) +81-45-680-1682

URL: www.yamashin-filter.co.jp/eng