that redefines the

status quo.

No more bubble trouble.

Bubbles in hydraulic and lubrication fluids can cause

major problems for monitoring equipment.

These bubbles can be mis-identified as abrasive contamination

by monitoring equipment and cause sudden equipment malfunction.

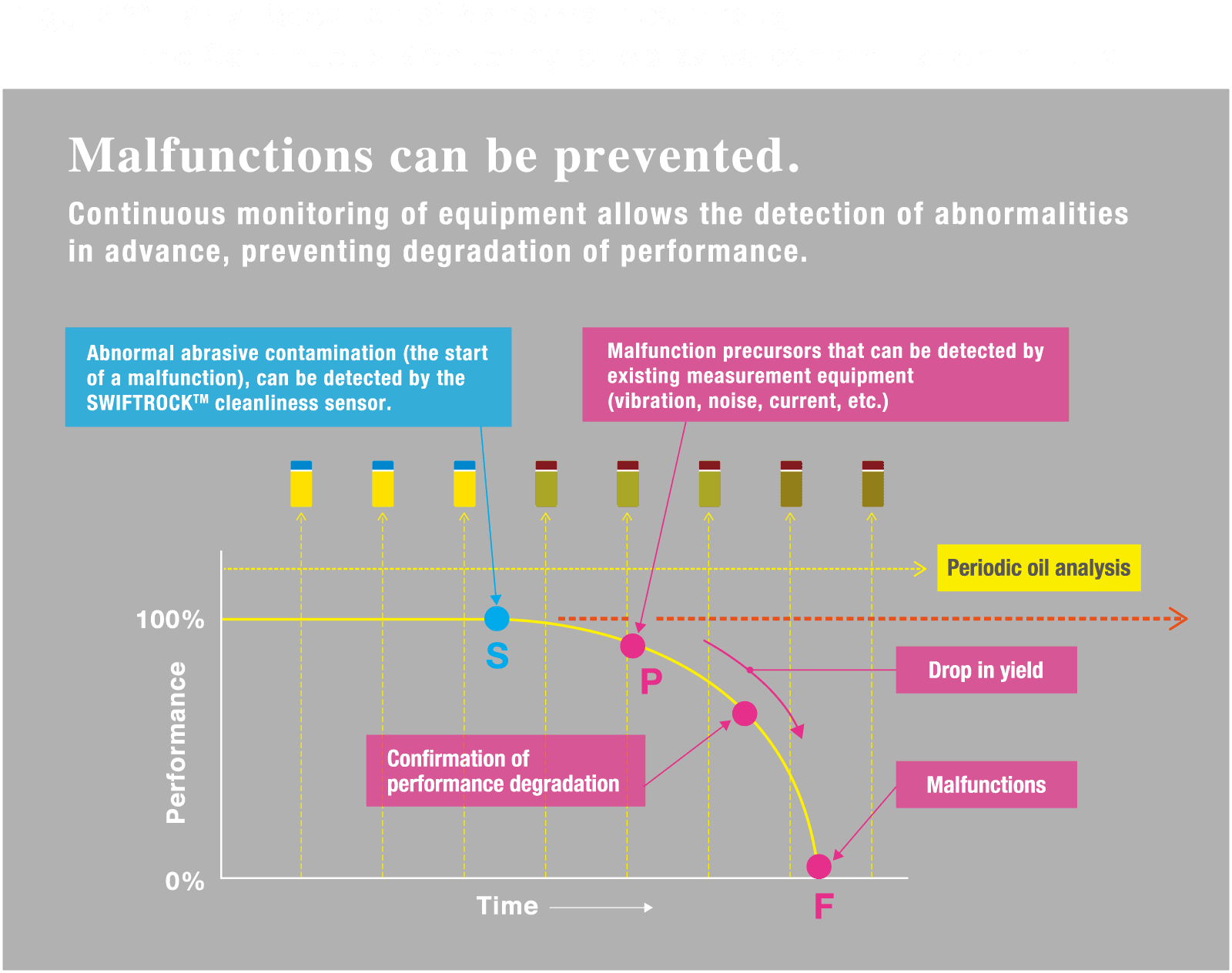

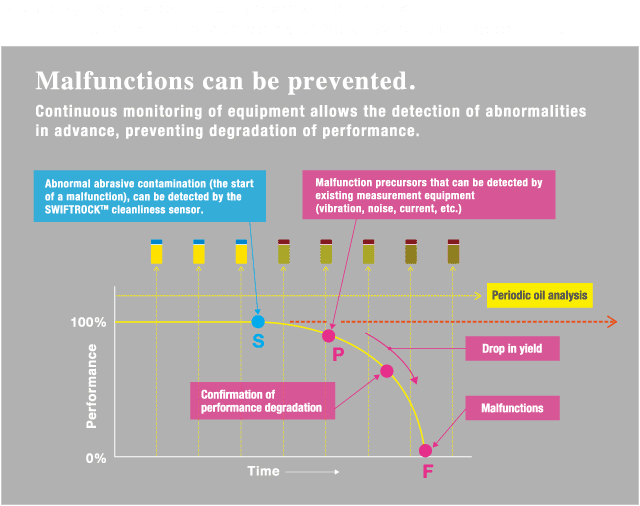

By using continuous monitoring that is not affected by bubbles,

we are now able to prevent problems that have long been

troublesome for people working in the field.

YAMASHIN-FILTER CORP. has developed SWIFTROCK™,

a new sensor that not only solves these problems, but can also

be installed at a much lower cost than ordinary optical measuring

equipment and end your “bubble trouble,” once and for all.

inspection of hydraulic and lubrication equipment.

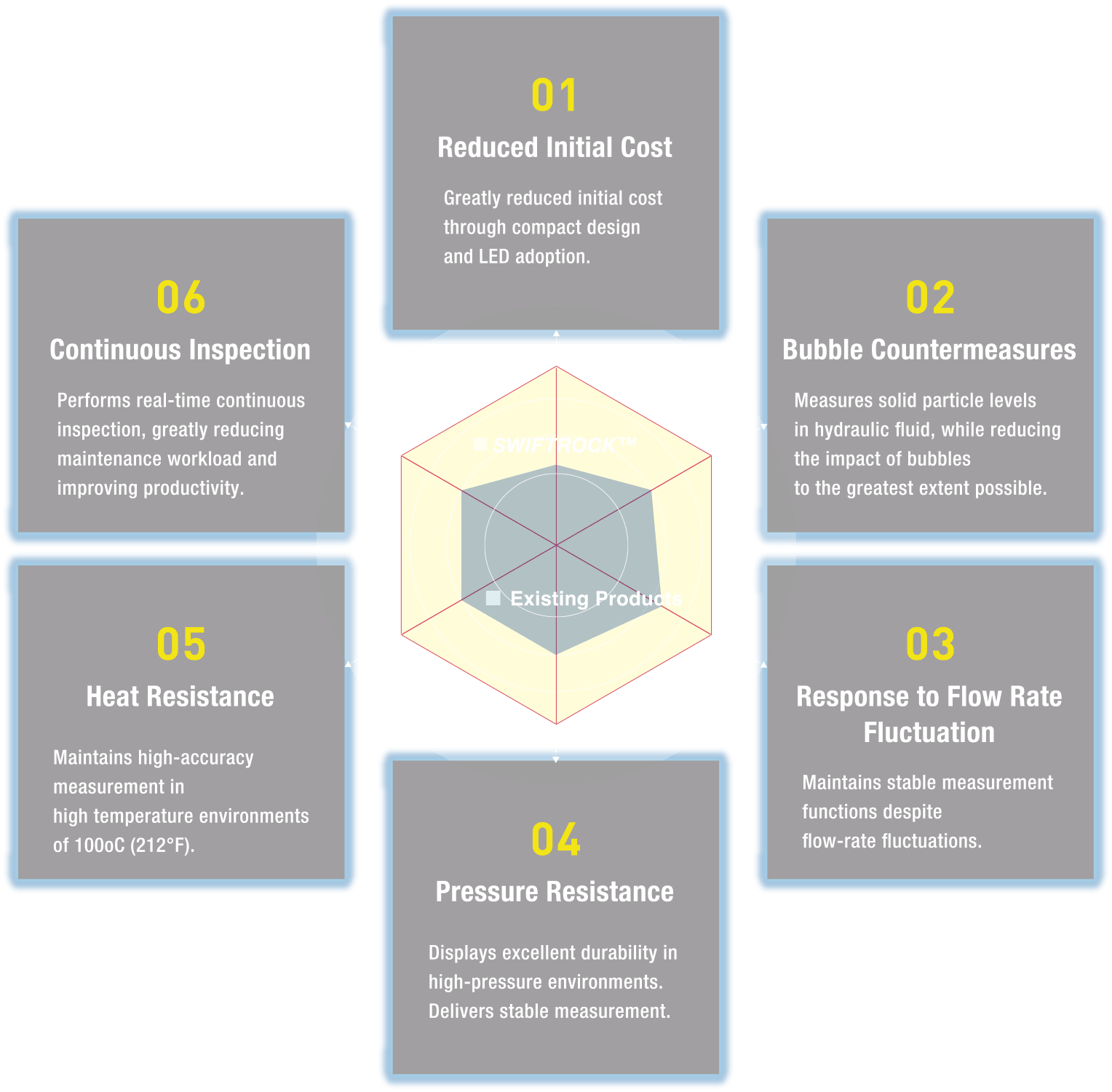

Here are six innovative features and functions

of SWIFTROCK™.

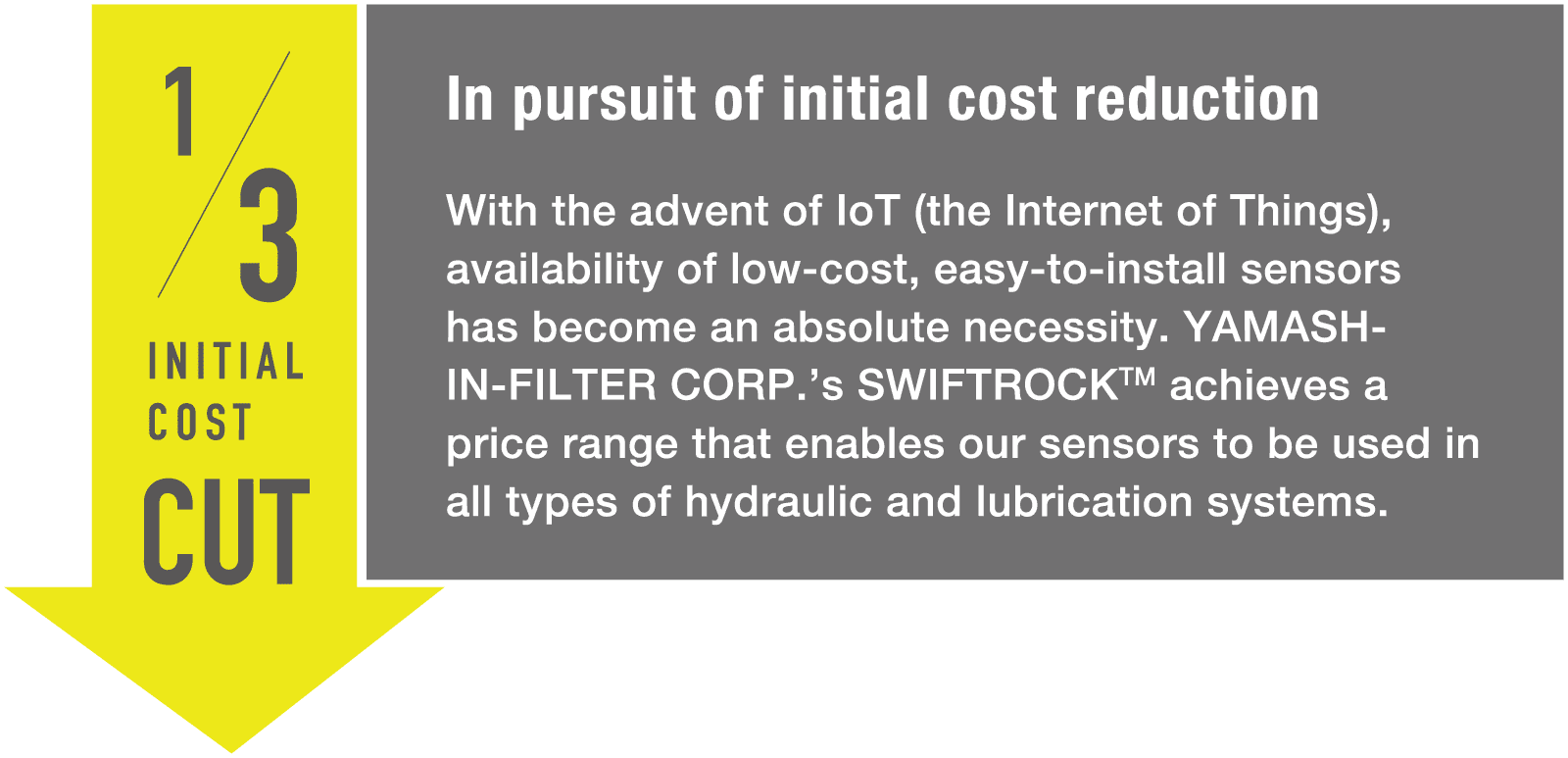

initial cost.

YAMASHIN-FILTER CORP.

harnessed our superior R&D

and engineering capabilities

to achieve unrivaled initial cost.

It is not unusual to see existing optical particle counters priced in the millions of yen (tens of thousands of US dollars). In contrast, SWIFTROCK™ is able to substantially reduce initial cost through the use of LEDs. The system’s compact size also makes it easy to install. The many features implemented through YAMASHIN-FILTER CORP.’s superior R&D capabilities make it possible to greatly reduce cost.

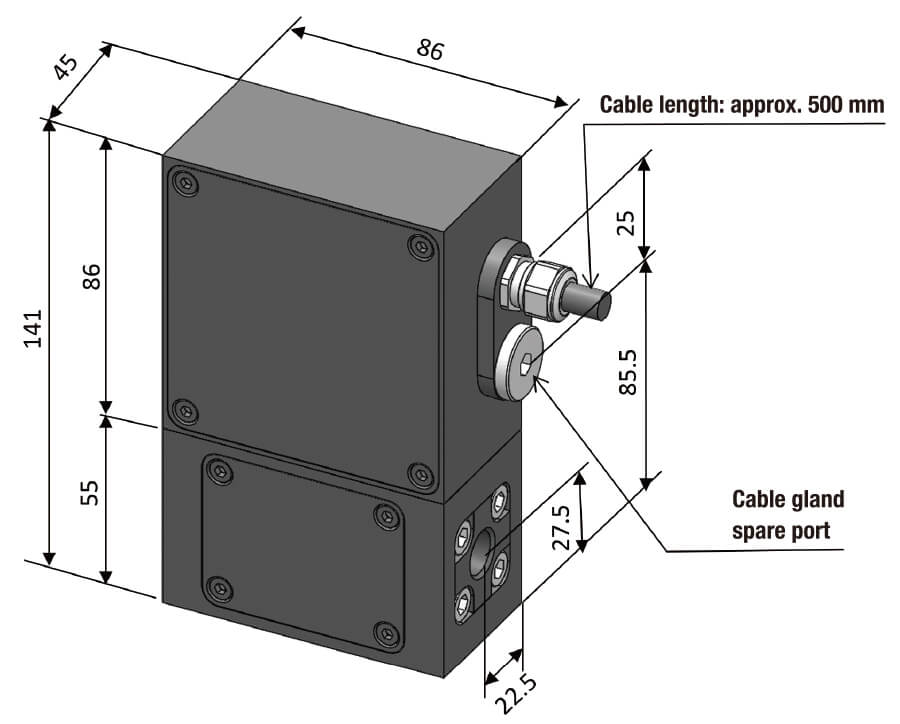

Advantages of

Compact design :

141mm × 86mm × 45mm (H × W × D)

5.5” × 3.4” × 1.8” (H × W × D)

Hydraulic and lubrication systems have become more compact. SWIFTROCK’s compact and robust design makes it easy to install in a wide variety of systems.

measurements that are

not influenced by bubbles.

Overcomes the greatest weakness

hindering the cleanliness monitoring

of hydraulic and lubrication fluids.

End your “bubble troubles”

once and for all.

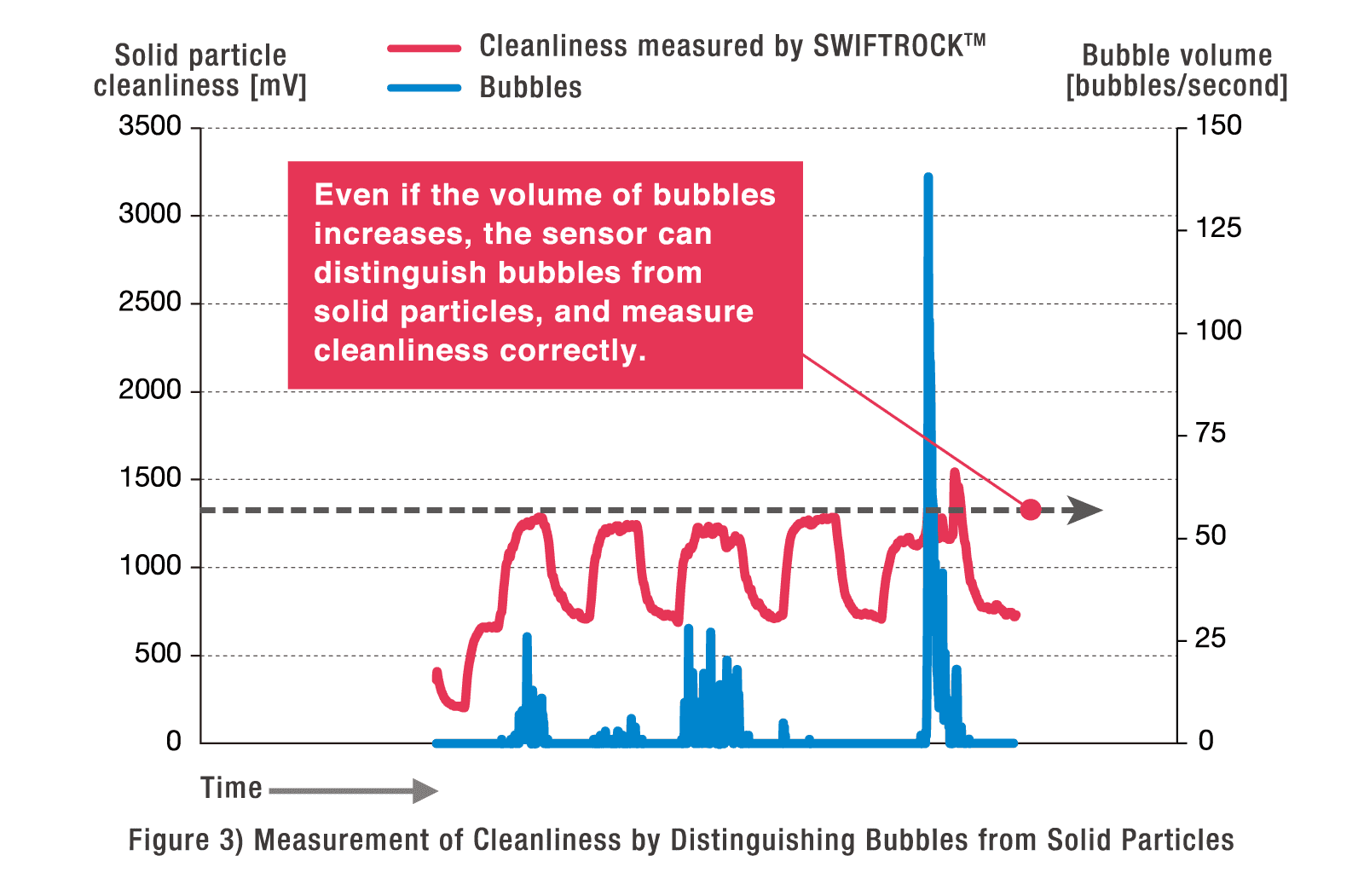

Because they are optical, existing particle counters

have the disadvantage of measuring bubbles as particles.

YAMASHIN-FILTER’s proprietary technology enables

SWIFTROCK™ to measure cleanliness accurately,

without misdetecting bubbles as contamination.

This successfully overcomes the greatest weakness hindering

the cleanliness monitoring of hydraulic and lubrication fluids.

Bubble

Bubble

Countermeasure Technology

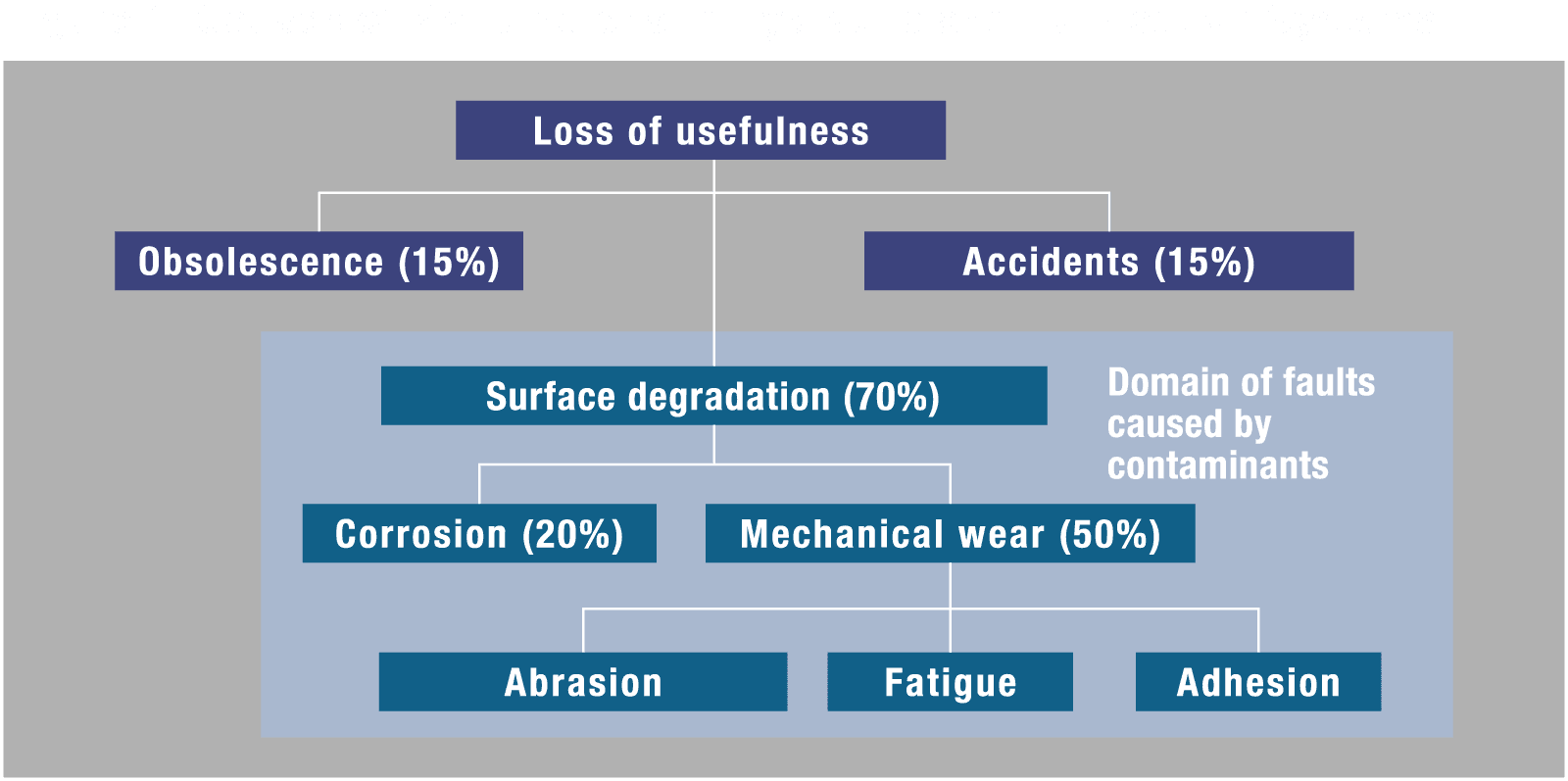

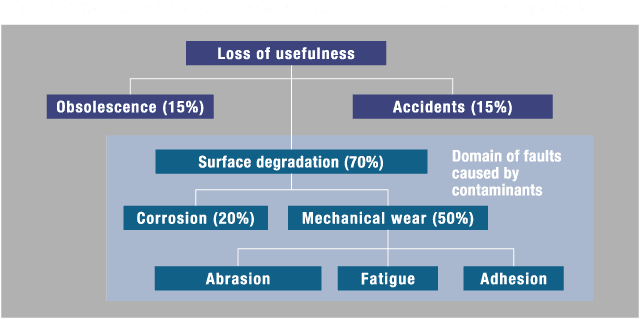

YAMASHIN-FILTER CORP. has successfully developed a technology for measuring bubbles and solid particles separately (patent pending), realizing cleanliness monitoring that is focused only on abrasive contamination, which is the greatest cause of malfunctions in hydraulic and lubrication systems.

flow rate fluctuations.

SWIFTROCK™ provides reliable performance, even

when the inflow rate is unstable.

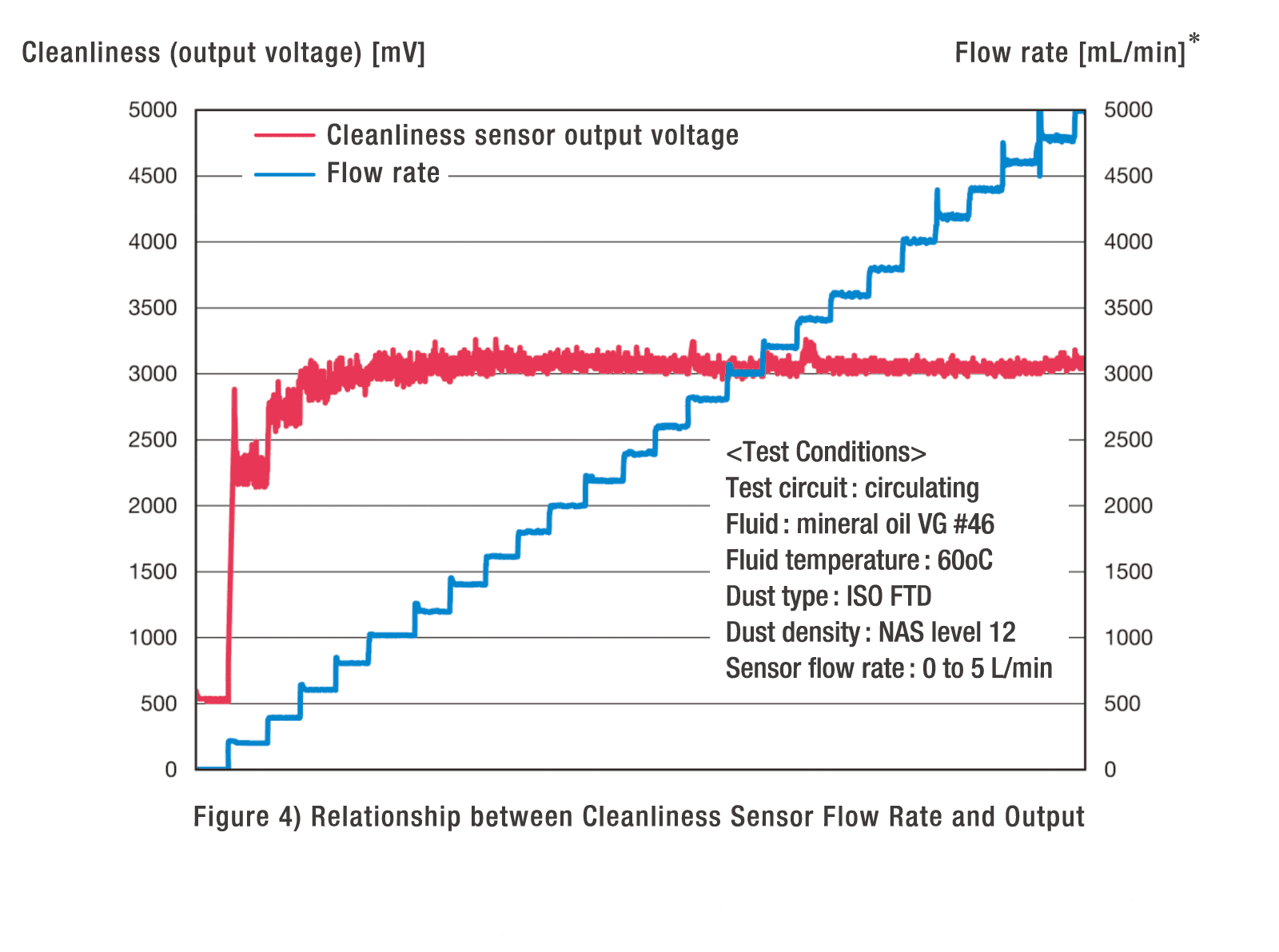

There are cases in which fluctuations in the flow rates of hydraulic systems prevent measurement by particle counters.

SWIFTROCK™ can perform accurate measurements of cleanliness within the range of 1.2 to 5.0 L/min. (0.26 GPM to 1.32 GPM)

Pulse Countermeasure Technology

Sensor output remains constant,

even when the inflow rate into the sensor varies.

There are always fluctuations in the flow rate in hydraulic and lubrication system circuits. YAMASHIN-FILTER CORP. has developed a proprietary technology to prevent such fluctuations from impacting performance (patent pending). This technology can be used for both inline and online applications.

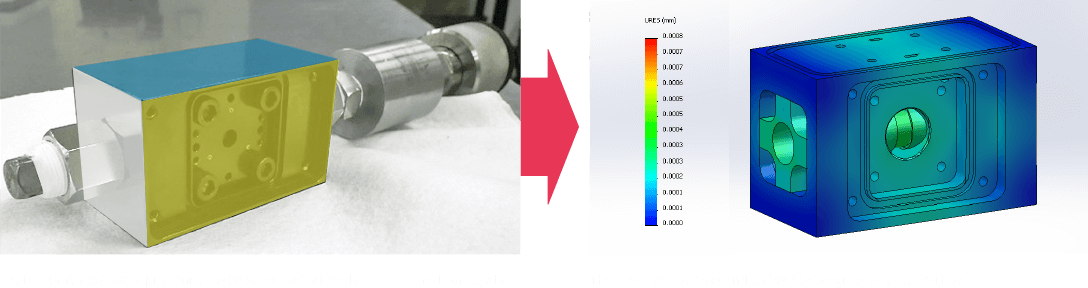

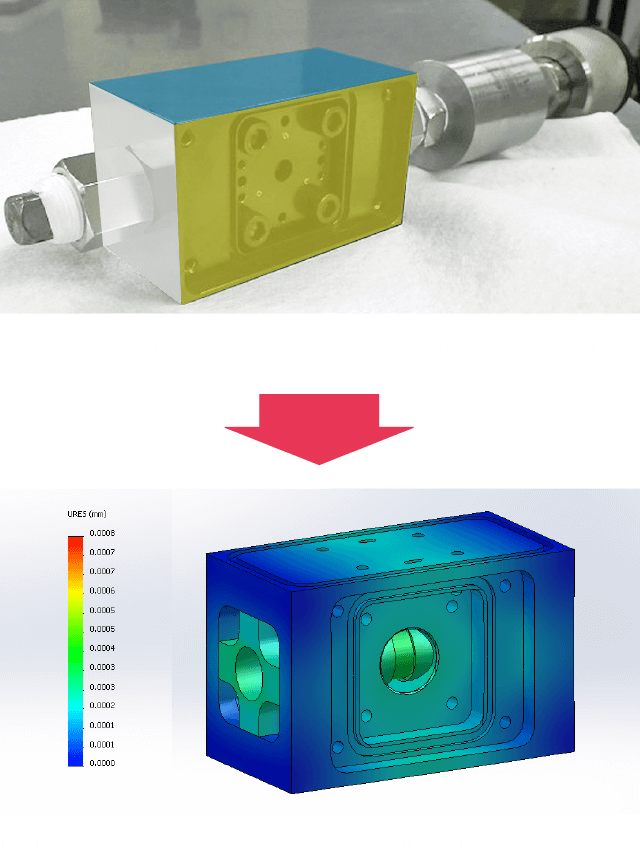

pressure.

Rigid and robust design enables installation on high pressure circuits.

SWIFTROCK™ accurately measures cleanliness under the harshest of conditions. In an impulse test, which tests resistance under high-pressure conditions, our design passed 2.1 million applications of 56 MPa (8,122 PSI) without plastic deformations, cracks, or leaks.

Pressure Resistant

Design Technology

SWIFTROCK’s safe and secure design exhibits no

plastic deformations, cracks, or leaks after 2.1 million

applications of 56 MPa pressure.

Construction machinery operates in harsh environments. YAMASHIN-FILTER CORP. which has the top market share in high-pressure filters for construction machinery, employs durable casing designs and robust manufacturing technologies. Our sensors can measure cleanliness accurately, even under high-pressure conditions. This is also a strength of SWIFTROCK™.

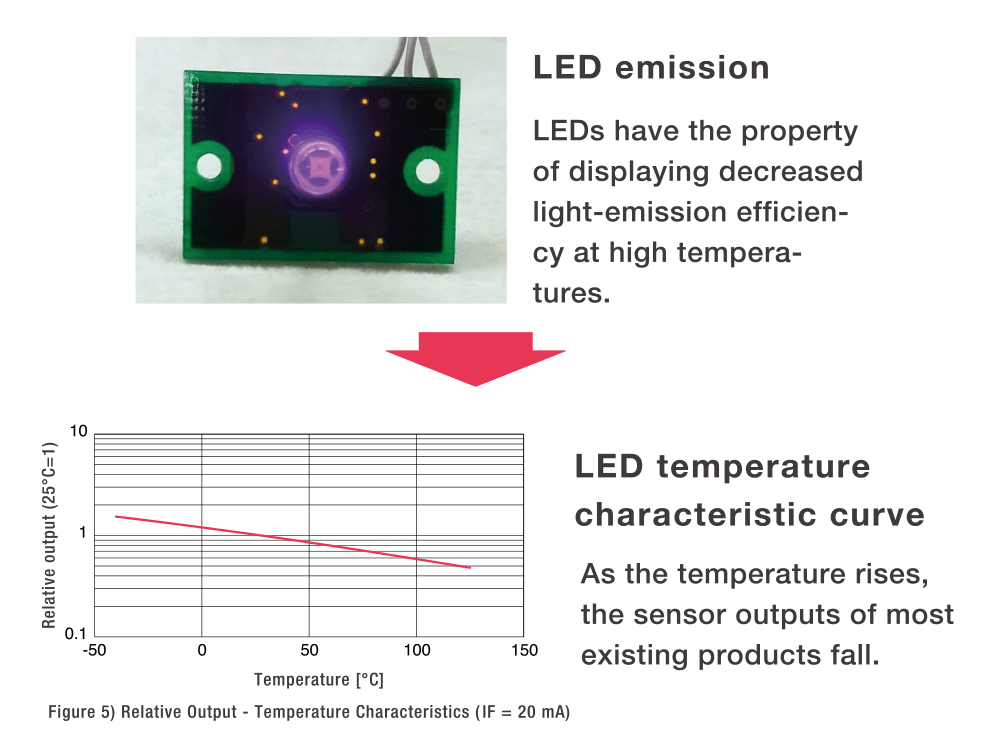

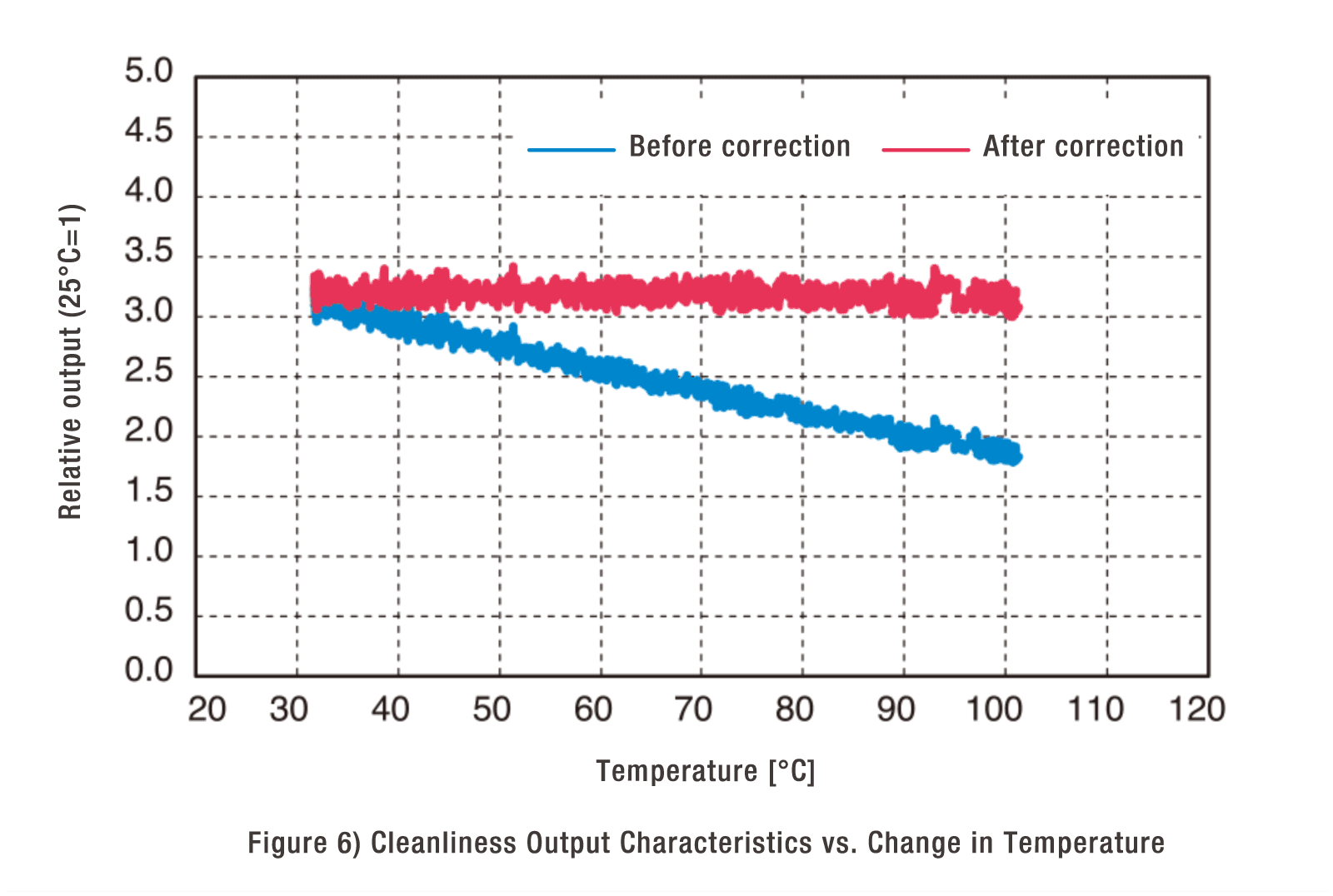

temperatures.

Able to measure cleanliness even

at high-temperature conditions

of 100℃ (212°F).

Although LEDs have the property of displaying decreased light-emission efficiency at high temperatures, SWIFTROCK™ has a built- in feature that adds a correction corresponding to LED temperature, enabling stable measurement.

Environmental Resistance Technology

Equipped with a built-in function to

add a correction factor corresponding

to LED temperature to sensor output.

Although LEDs display decreased light-emission efficiency at high temperatures, our temperature correction feature enables use under temperature conditions ranging from -30oC to 100oC (-22°F to 212°F).

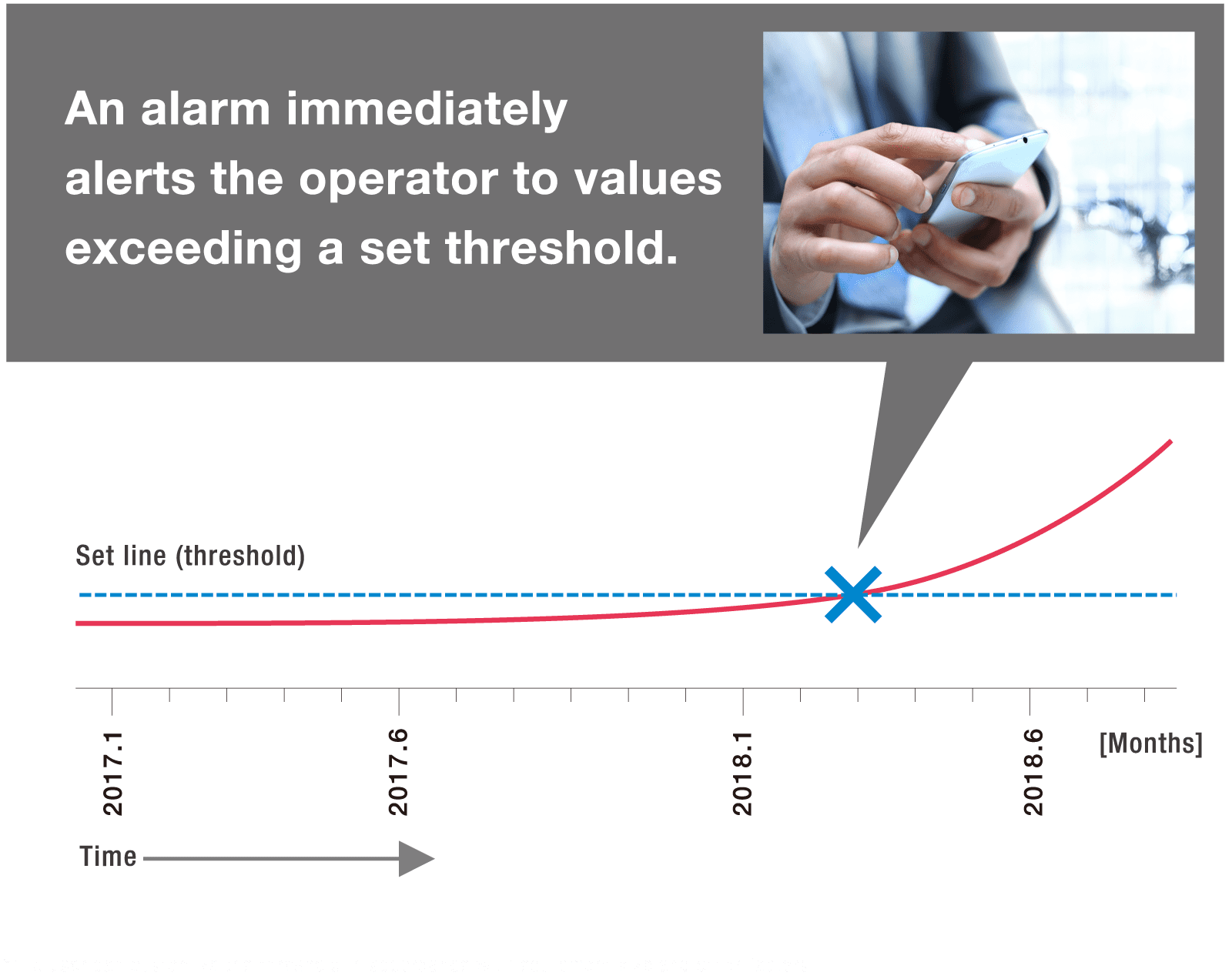

Helps reduce workload,

supporting production sites.

SWIFTROCK™ minimizes the amount of system maintenance required through remote notifications that can be triggered when a value exceeds the threshold, eliminating downtime.

SWIFTROCK™ supports ICT and the Transition

to IoT in a Wide Range of Industries.

SWIFTROCK™ can be used in all industrial fields. With the advent of IoT comes the creation of smarter and more productive environments enabling end-users to monitor systems in real-time at any time.

YAMASHIN-FILTER CORP.’s SWIFTROCK™ supports the transition to IoT

and the creation of smart factories in all industries.

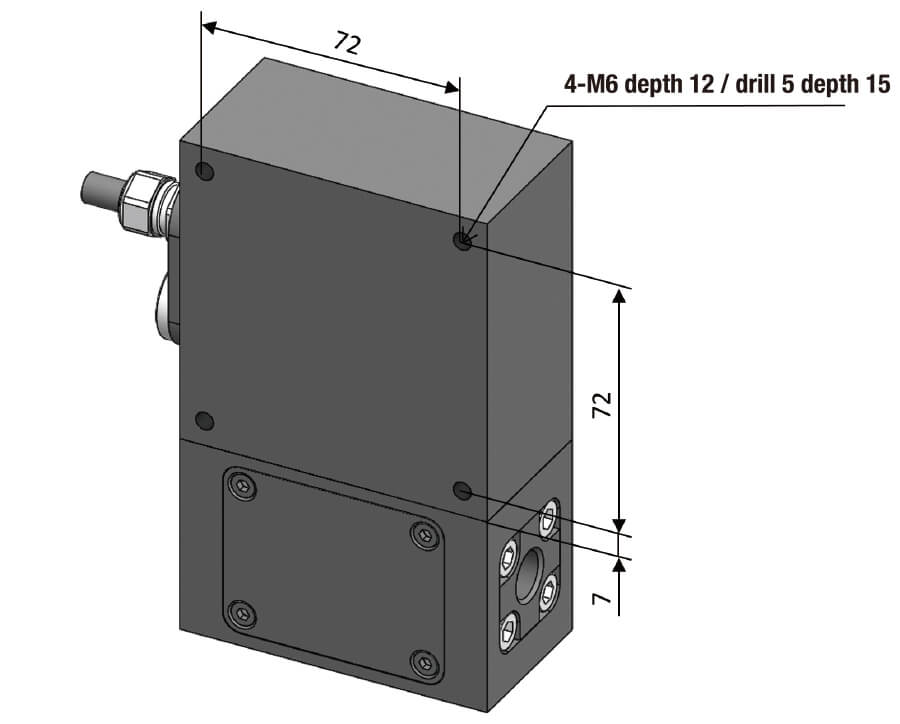

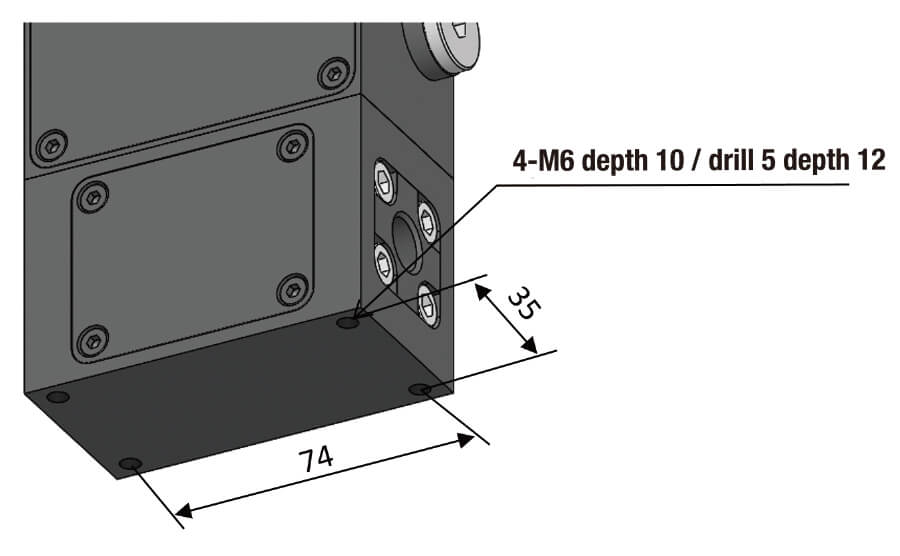

Dimensions

Dimensions

Specifications

Specifications

| No. | Items | Specification | Remarks |

|---|---|---|---|

| 1 | Maximum working pressure | 42 MPa (6,091 PSI) | - |

| 2 | Working fluid temperature range |

-30°C to 100°C -22°F to 212°F |

- |

| 3 | Working flow rate range | 1.2 to 5.0 L/min. | Approximate standard |

| 4 | Measurable fluids | Fluids compatible with nitrile rubber sealant and transparent to LED light. |

Cannot measure emulsions or cloudy fluids mixed with water. |

| 5 | Measurable cleanliness range |

AS4059 (former NAS) Level 6 to 12, or equivalent |

Level ±1 (Approximate) |

| 6 | Measurable particle diameter/count |

- | Inferred from the above measurement results. |

| 7 | Internal sealant | Nitrile rubber | - |

| 8 | Attachment to main unit | 9/16-18 UNF | - |

| 9 | Dust and water resistance | IP68 | - |

| 10 | Power | DC9V to 36V | - |

| 11 | Piping port size | 2-9/16-UNF | No specification of flow direction. Either port can be used for both in/out. |

Contact us: YAMASHIN-FILTER CORP.

1-1-8 Sakuragi-cho, Naka-ku,

Yokohama 231-0062, Japan

FAX: (Sales section) +81-45-680-1682

URL:www.yamashin-filter.co.jp/eng

E-mail:swiftrock@yamashin-filter.co.jp