A great variety of equipment is used in machining plants. The amount of oil mist it produces and the environmental conditions within such facilities depend heavily on the equipment’s construction as well as the machining methods and processes being employed. Oil mist can be categorized as either the airborne oil particles created when cutting oil supplied to a machining area is micronized through shearing as it collides with the object being cut or a tool rotating at high speeds, or the oily smoke generated from the heat of the machining process. The airborne oil particles are often generated in large quantities in high-pressure lubrication processes and high-speed cutting and grinding processes where cutting oil is subjected to high shear forces. Among these oil mist particles, those with a large particle diameter condense in a relatively short time, while those with a fine particle size are released into the atmosphere before condensation progresses.

Packaged Air Conditioner (Floor)

A heat-pump unit consisting of one outdoor unit, multiple indoor units, and refrigerant piping. The indoor unit is embedded in the ceiling, eliminating the need for ductwork and enabling individual control. Used in small and medium buildings and stores.

Types of available air filters

This long-lasting, pleated filter removes particles with a diameter of more than 5 μm.

This filter has a medium collection efficiency for particles with a diameter less than 5 μm.

Capable of dealing with a variety of gaseous substances within the air, this product offers superior purification performance.

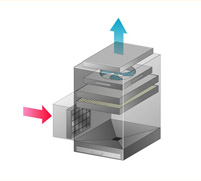

Exhaust Treatment Unit (Factory Mist)

In machining plants, small-diameter particles of oil mist generated when cutting oil is sheared and micronized are discharged into the atmosphere. This device uses an air filter to remove these oil mist particles before exhausting the air into the atmosphere.

Types of available air filters

This long-lasting, pleated filter removes particles with a diameter of more than 5 μm.

This filter has a medium collection efficiency for particles with a diameter less than 5 μm.

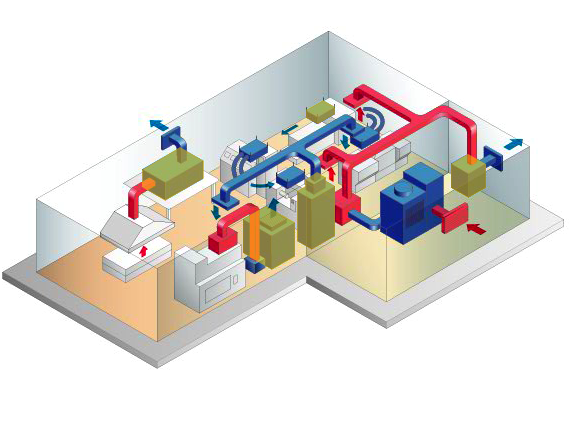

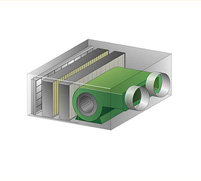

Mist Collector (Open Air Intake)

This device uses an air filter to remove the oil mist floating around the factory, in a way that fits with your facility’s overall ventilation system. There are two types: a distributed system in which relatively small purifiers are installed in various places around the plant to clean the air without the use of ductwork, and a centralized system in which a large purifier is installed in a single location and collects air through ducts.

Types of available air filters

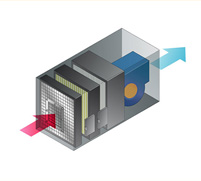

Mist Collector (Direct Intake)

This device removes the oil mist generated in large quantities by machining equipment during high-speed cutting and grinding processes as well as high-pressure lubricated processes that subject cutting oil to high shear, then discharges the purified air into the atmosphere.

Types of available air filters

Clicking on a product image above will direct you to the corresponding product page on the AQC website (Japanese).