Most industrial coating is applied through spraying, a process that consists of coating and drying. The paint used in the coating step is diluted with a solvent then atomized to apply its solid portion to the object being coated. Virtually all of the solvent added to the coating is released into the atmosphere, with the solids in overspray remaining as paint sediment in the circulation basin of the paint booth. Thus, the materials discharged into the atmosphere by the coating step include volatized dilution solvent, while those emitted by the drying step also include some solvent.

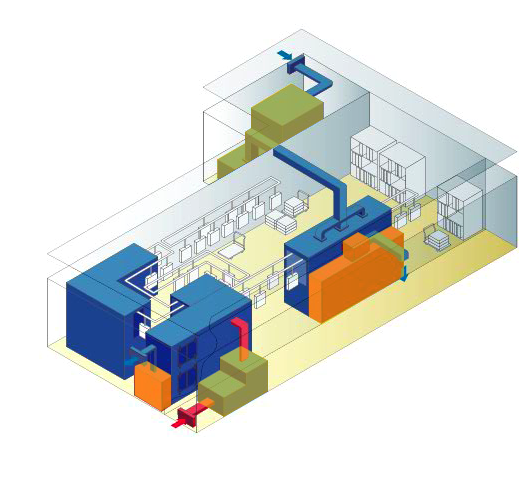

External-Air Treatment Unit (Air Supply)

To produce a high-quality coating, this device purifies contaminated external air using an air filter before supplying it to the paint booth.

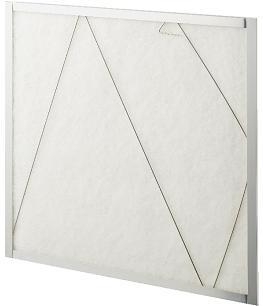

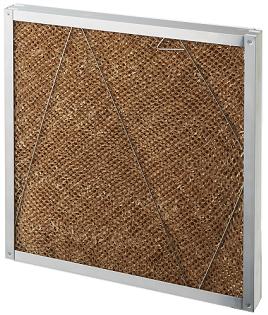

Types of available air filters

This long-lasting, pleated filter removes particles with a diameter of more than 5 μm.

This filter has a medium collection efficiency for particles with a diameter less than 5 μm.

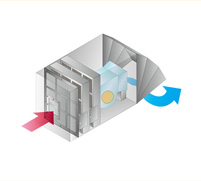

Exhaust Treatment Unit (Paint Booth)

Exhaust from a paint booth contains odors from solvents and decomposition, etc. as well as paint dust from overspray. This device uses an air filter to remove these substances before discharging the air into the atmosphere.

Types of available air filters

This long-lasting, pleated filter removes particles with a diameter of more than 5 μm.

Exhaust Treatment Unit (Drying Furnace)

Curing ovens decompose the solvents and resins within paint coatings as they dry them. This device uses an air filter to remove these substances before discharging the air into the atmosphere. It also filters the air supplied to the oven to prevent foreign material from adhering to the coating during the drying process. In some cases, the ability to handle high temperatures is required.

Types of available air filters

Clicking on a product image above will direct you to the corresponding product page on the AQC website (Japanese).